With smart software and advanced machines, we turn engineering data into error free wiring and efficient production.

Optimation was founded on one clear insight: the future of panel building runs on data. As early as the start of AES Engineering in 2006, we saw how complete digital designs were created in EPLAN, while that valuable data was barely used on the shop floor. Panel building remained manual, slow and prone to errors.

We saw a missed opportunity and enormous potential.

In 2019, we changed course and founded AES Panelshop: our own fully digital panel building department. There, we proved what happens when engineering data takes the lead and wires are pre-assembled automatically: higher speed, fewer errors and a far more efficient shop floor.

That hands-on experience became the foundation of Optimation. Today, we help panel builders and machine builders take the same step: from traditional building to a data-driven, scalable and future-proof production process.

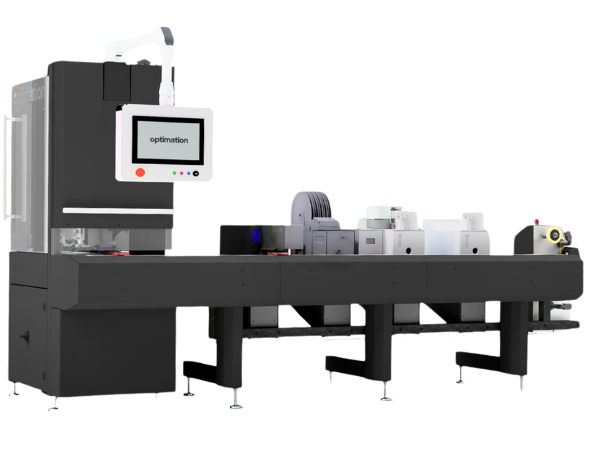

The Optima platform and our Testudo and Castellum systems were developed and tested for years within AES Panelshop, our own fully digitalised panel building department.

In daily operations, we have clearly demonstrated what digitalisation delivers: higher speed, fewer errors, immediate savings in labour hours and a production process that scales effortlessly.

We pre-assemble all wires entirely based on engineering data, in a project-specific sequence for both wire production and panel connection. This enables the shop floor to work faster, more consistently and with significantly more peace of mind.

Thanks to Optima’s digital work instructions, even employees without a technical background can begin producing with ease from day one.

This proven practice is the foundation of Optimation. What we deliver today is not theory, but a solution that runs daily in real panel building and delivers measurable results.

Accelerate your production and reduce labour hours by working smarter. By combining intelligent software with automated wire processing, you shorten lead times and minimise manual work while quality improves at the same time.

With the Optima platform and our automated systems, you always produce wires in the correct length, sequence and quality. You work error free and consistent with real time insight into progress and performance on the panel building floor.

With Optimation, you take the step today toward the panel building of tomorrow. By using your data as the central driver and digitalising your processes, you build a future proof organisation that is ready for further automation and growth.

Panel building is under pressure. Lead times must decrease, quality requirements are rising and skilled technical personnel are difficult to find. Companies that do not change now increasingly run into problems with planning, capacity and quality control.

The solution is not working harder, but establishing a production process that is predictable, scalable and professionally structured. A shop floor where every step is logical, repeatable and verifiable. Where teams can move faster and lose less time on rework, waiting and improvisation.

Companies that take this step notice the difference immediately:

More calm. More clarity. More output.

And above all: far less dependence on personnel who are increasingly difficult to find.**

At Optimation, we design production processes so organisations are ready for growth. We help you structure your processes, simplify work and organise the shop floor for the future. This creates a stable foundation that allows you to keep delivering even when pressure increases.

Tomorrow starts today. The companies that modernise now will become the winners of the next generation of panel building.

With our solutions, you make panel building faster, error free and more efficient. These numbers show exactly what digitalisation delivers in practice.

At Optimation, you work with the latest technology in machine building and software. Together, we build the future, and you can be part of it.

You will have the space to learn, experiment and grow alongside our young team. Ready to give your career a flying start? Join Optimation!

Here you will find answers to the questions we are most frequently asked about digitalisation, Optima and our machines.

For panel builders, machine builders and OEMs that want to digitalise and make their production process scalable and future proof.

Digitalisation can be phased. You can start with Optima and add machines later. This spreads the investment while already giving you benefits from day one.

No. We align with your existing processes. Small steps ensure your team sees results quickly and the transition feels natural.

Testudo is a semi automatic machine for cutting and finishing wires.

Castellum goes a step further with fully automatic wire assembly including cutting, marking and finishing.

Yes. With the clear instructions in the Workfloor app, even non specialists can wire panels without errors.

Want to know how Optimation can digitalise and accelerate your panel building? During a meeting, we will show you how our software and machines work in practice and what this delivers for your organisation.