With smart software and advanced machines, we turn engineering data into error free wiring and efficient production.

✔ EPLAN configuration & data structure

We help you set up EPLAN intelligently and structure your engineering data logically. You can then expand and maintain this yourself.

✔ Data validation & process setup with Optima

We ensure that your engineering data flows correctly into the Optima platform.

✔ Operation of Testudo & Castellum

We guide you in connecting the Optima platform to Testudo and Castellum.

✔ Guidance throughout your digitalisation process

Whether you start small or take the full automation step right away, we help you get started, train your team and ensure your processes are ready for the next step.

From raw engineering data to an automated production process.

At many companies, valuable EPLAN data gets stuck in the engineering phase. Without a connection to the shop floor, manual work, errors and inefficiency continue to dominate.

Optimation makes that data work for you. We help you set up EPLAN intelligently, link your projects to the Optima platform and support panel building through Workfloor, Testudo and Castellum.

This is how we guide you step by step toward a digital, scalable and future-proof panel building process. You stay in control, from engineering to assembly.

We start with an analysis of your current engineering process. Together, we look at how your EPLAN data is being used, where bottlenecks exist and how we can transform this into an efficient, data-driven way of working.

✔ Result: Insight into your current process and a clear plan to use your engineering data smarter and more efficiently.

Our consultancy engineers work with your team to establish a solid digital foundation. Symbols, macros, databases and wire definitions are set up precisely and fully aligned with the Optima platform.

✔ Result: A solid, uniform data structure in EPLAN that aligns seamlessly with Optima and is ready for digital production.

We koppelen jouw EPLAN-data rechtstreeks aan het Optima-platform. Vanuit daar regel je werkvoorbereiding, planning en monitoring. Medewerkers werken met de Workfloor-app, die duidelijke instructies geeft en foutloos bedraden mogelijk maakt, ook zonder technische achtergrond.

✔ We connect your EPLAN data directly to the Optima platform. From there, you manage work preparation, planning and monitoring. Employees work with the Workfloor app, which provides clear instructions and enables error-free wiring, even without a technical background.

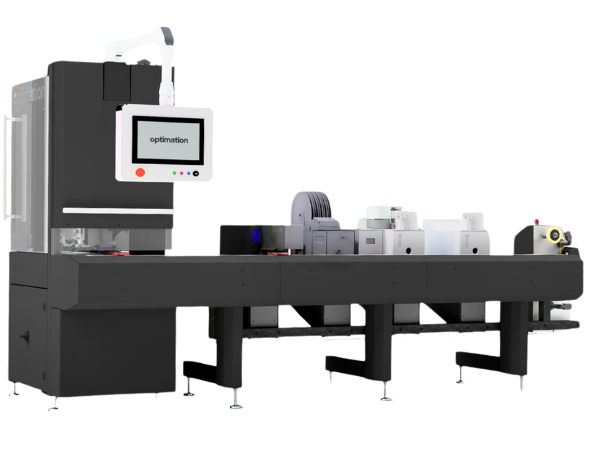

Ready for automation? Then take the next step with Testudo and Castellum. These systems work directly with the data from Optima, ensuring your engineering effort delivers maximum value and the wiring process becomes fully automated.

✔ Result: Your wire production runs directly on the correct data and stays fully in sync with Optima — faster, more stable and ready for further automation.

We train your team to work independently with our software and systems. Even after implementation, we continue to support you with optimisations, updates and expansions.

✔ Result: A team that works independently with Optima and the machines, with fewer errors and greater efficiency, and a system that easily grows along with your company.

With dashboards in Optima, you gain real-time insight into progress, quality and capacity. This allows you to see where time and resources are being lost and make adjustments immediately. The data forms the foundation for continuous improvement and further automation.

✔ Result: Immediate insight into your production and clear steering information to improve processes, save time and automate further.

Digitalisation starts with strong engineering data. Schematics must be complete, consistent and logically structured, otherwise the shop floor can never produce quickly or error-free.

This requires a different way of designing: engineers must draw in the way a panel builder actually works. This means clearer schematics, better coding and more detail.

Anyone who wants to work with the Optima platform must be willing to take that step. This requires commitment from both management and employees. Without well-developed engineering data, automation is simply not achievable.

Optimation helps companies improve schematics, streamline processes and prepare the shop floor for data-driven production. This way, Optima delivers visible results from day one.

Digitalisation only truly works when the entire organisation moves along with it. We make sure that happens.

Here you’ll find answers to the questions we are most frequently asked about digitalisation, Optima and our machines.

For panel builders, machine builders and OEMs that want to digitalise and make their production process scalable and future proof.

Digitalisation can be phased. You can start with Optima and add machines later. This spreads the investment while already giving you benefits from day one.

No. We align with your existing processes. Small steps ensure your team sees results quickly and the transition feels natural.

Testudo is a semi automatic machine for cutting and finishing wires.

Castellum goes a step further with fully automatic wire assembly including cutting, marking and finishing.

Yes. With the clear instructions in the Workfloor app, even non specialists can wire panels without errors.

Want to know how Optimation can digitalise and accelerate your panel building? During a meeting, we’ll show you how our software and machines work in practice and what this means for your organisation.