From EPLAN to the shop floor

How to get real value from your engineering data

Many companies invest in EPLAN but use only a small part of its potential. Schematics are neatly created, yet on the shop floor improvisation, uncertainty and error prone manual work still occur. The result is a process that remains dependent on experience and is rarely truly predictable.

The step from EPLAN to the shop floor is therefore the most underestimated link in the entire panel building process.

1. Everything depends on data quality

A shop floor can only work efficiently if the engineering data is complete. That sounds obvious, but in practice Optimation often sees the same bottlenecks:

-

Missing or duplicate codes

-

Incomplete component data

-

Different naming conventions per engineer

-

Multiple drawing styles within one company

-

Inconsistent wire structuring

- No established standards

Even small deviations cause delays, misinterpretations and rework.

Anyone taking digitalisation seriously must start by streamlining this data.

2. Engineers must design the way assemblers work

A schematic is only useful when it makes sense to the person building the panel.

That’s why engineering must do more than just draw. Engineering needs to translate the work process into data and structure.

This means:

- Clear wire routes

- Logical sequences

- Uniform namingFunctionally structured layout

- Accurate and complete component data

- A drawing style followed by all engineers

The closer engineering and production align, the faster and more error free the process becomes.

3. Work preparation becomes the heart of production

When you use data as the foundation, work preparation shifts from creating lists to checking and releasing correct information.

The shop floor no longer needs to search, interpret or correct — they can execute directly from the system.

This immediately delivers:

-

Less miscommunication

-

Less dependence on experience

-

Shorter lead times

-

More calm on the shop floor

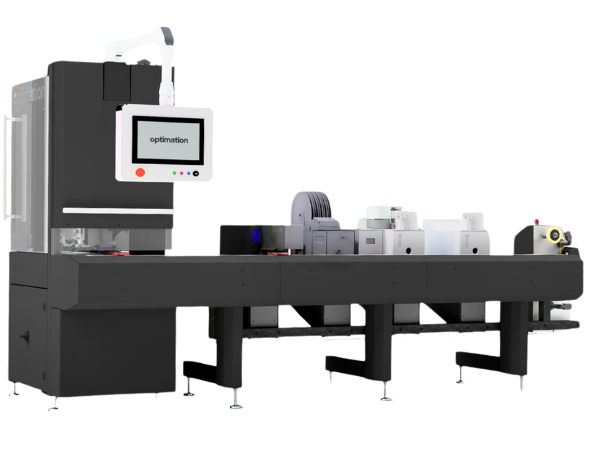

4. From data to automatic wiring

Once the engineering data is correct, there is room for further automation.

Systems like Testudo and Castellum can produce wires in the exact length and sequence, entirely based on what’s in EPLAN.

This gives companies:

- Speed

- Repeatability

- Quality no longer dependent on people

- Freedom to scale without extra staff

This is the point where digitalisation truly starts to deliver value.

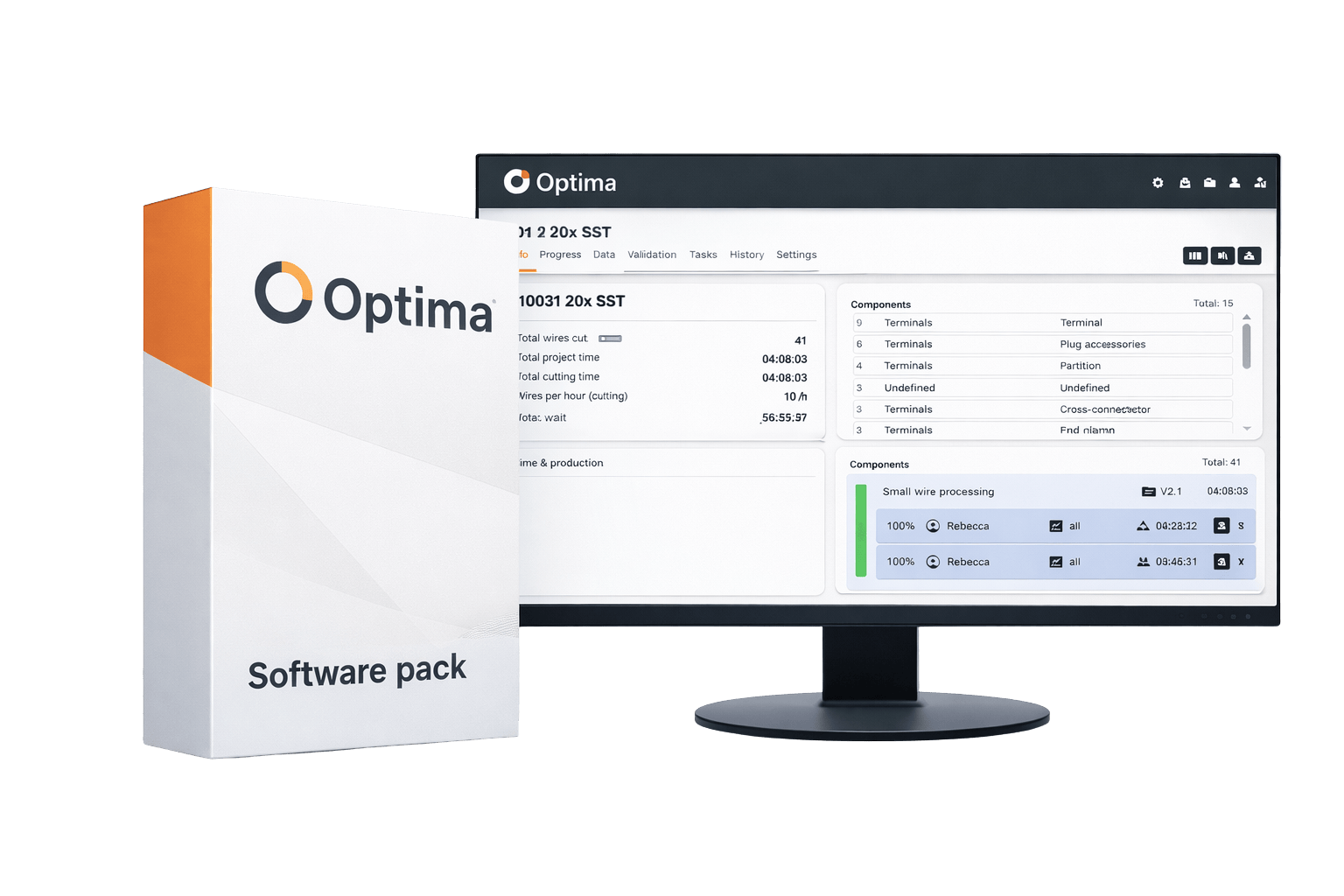

5. Optima connects engineering with the shop floor

Optima ensures that data from EPLAN is directly available for production.

The shop floor receives clear instructions, the team leader has real time insight, and the manager immediately sees where time and capacity are lost.

For companies, this means:

- Perfect alignment between EPLAN and assembly

- Fewer errors

- Shorter lead times

- Full control over production

Optima turns engineering data into a powerful production tool

6. Every day, the results speak for themselves

In companies where the foundation is in order, we see the same results repeated:

- Less rework

- Fewer rejects

- Faster onboarding of staff

- Predictable planning

- Stable quality

- Higher production per employee

It works. Every day.

Conclusion

The step from EPLAN to the shop floor is not a technical problem, but a data problem.

Companies that get their engineering data in order lay the foundation for more efficient assembly, higher quality, and further automation.

Optimation helps companies make that transition and guides the entire process — from data quality to the shop floor, and from work preparation to automated wiring.

The future of panel building starts with good data.