With smart software and advanced machines, we turn engineering data into error free wiring and efficient production.

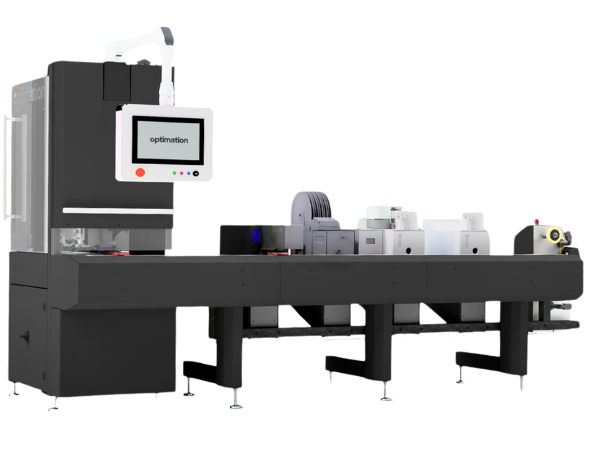

Castellum is the ultimate machine for full wire automation, faster, smarter and more flexible than any other system. Thanks to its modular design, you choose exactly the functions your production requires, while the Optima platform controls every wire entirely based on your EPLAN data.

Castellum works with a wide range of crimping machines, including the equipment you already use. This allows you to automate without major additional investments.

The result: maximum output, minimal errors and a significantly lower cost per panel. Castellum is the new standard in automated panel building.

The Castellum automates the entire wire-processing workflow: measuring, cutting, marking, crimping and bundling in one continuous flow.

Where this work is normally manual, slow and error-prone, the Castellum delivers consistent quality, high speed and fully repeatable output — regardless of operator experience.

The result: higher capacity, fewer failures and a production process that keeps running smoothly.

Thanks to its direct integration with the Optima platform, the Castellum becomes more than a machine. It’s a strategic step toward fully digitalised panel building.

Your engineering data is translated one-to-one into perfectly prepared wires — fully automatic and fully traceable.

At a time when skilled technicians are increasingly scarce, the Castellum makes your production less dependent on specialised labour and prepares your organisation for the next generation of smart, scalable panel building.

Have questions about how the Castellum works or how it fits into your production? You’re not the only one. Below you’ll find answers to the most common questions we receive from customers. From installation to integrating it with the Optima platform and Workfloor — everything is clearly explained for you.

Optima is designed to work seamlessly with Testudo and Castellum, but it can also be integrated into existing production processes.

No. You can start with Optima and Workfloor only. You can always add the Testudo or Castellum later.

We use the data from EPLAN (for example Pro Panel) as the foundation. Optima makes this data directly usable for work preparation, production and machine control.

Optima is our software platform that validates engineering data, connects it to the shop floor and provides real time insight into production.

Yes. We provide on site or online training so your team can work independently with Optima, Testudo and Castellum.

We provide remote support, software updates and on site service when needed, ensuring your system keeps running at its best.

Do you have questions about the Castellum or want to explore what full wire automation could mean for your production?

Our team is happy to think along with you and provide honest advice on how the Castellum fits your process, your capacity and your growth plans.

Want to know more?

Send us a message or call us directly, we’d be happy to get to know you..