Why panel building needs to digitalise now

Panel building is at a tipping point. Customers demand shorter lead times, projects are becoming more complex and skilled technical staff is increasingly hard to find. At the same time, much of the work is still done manually, often with schematics that lack the level of detail needed for efficient production.

The result is delays, errors, rework and high costs.

Digitalisation is no longer a future plan, but an immediate necessity.

1. Pressure on lead times is increasing

Industries expect faster delivery, but panel builders often still work with processes designed for a time when schedules were more flexible.

Manual wiring, separate lists, Excel overviews and verbal communication inevitably cause delays.

Companies that get their data in order notice an immediate difference:

-

Less searching

-

Fewer wiring errors

-

Less improvisation

-

Faster assembly

Lead times become predictable instead of a guess.

2. The quality of schematics determines everything

he biggest bottleneck in digitalisation is rarely in production itself, but in the engineering data.

Schematics that are incomplete or inconsistent cause misunderstandings on the shop floor and errors that need to be corrected later.

Digitalisation only works if:

- Codes are consistentComponent data is accurateNaming is uniformWire groups are logically structuredEngineering thinks like a panel builder

The better the schematic, the stronger the production.

3. The shortage of skilled staff is not going away

The influx of skilled technical staff continues to decline while demand keeps growing.

Companies that continue to rely on manual work face increasing pressure.

Digitalisation makes production:

- Less dependent on experienceLess prone to errorsScalable without extra staffCalmer and more organised on the shop floor

It is the only sustainable way to increase capacity.

4. EPLAN data is more valuable than you think

Many companies invest in EPLAN but use only a fraction of its capabilities.

The data it generates is exactly what’s needed to enable automation, provided it is used fully and consistently.

Anyone moving from EPLAN to a data driven shop floor must take one step:

improve the quality of their engineering data.

That’s where the biggest gains lie.

5. From data to production in practice

At companies that get their data in order, we see the same results:

- Up to 40 percent faster assembly

- Drastic reduction in errors

- Less rework and scrap

- Consistent quality

- More calm and overview on the shop floor

- Shorter onboarding times for new staff

Digitalisation works, as long as the foundation is right.

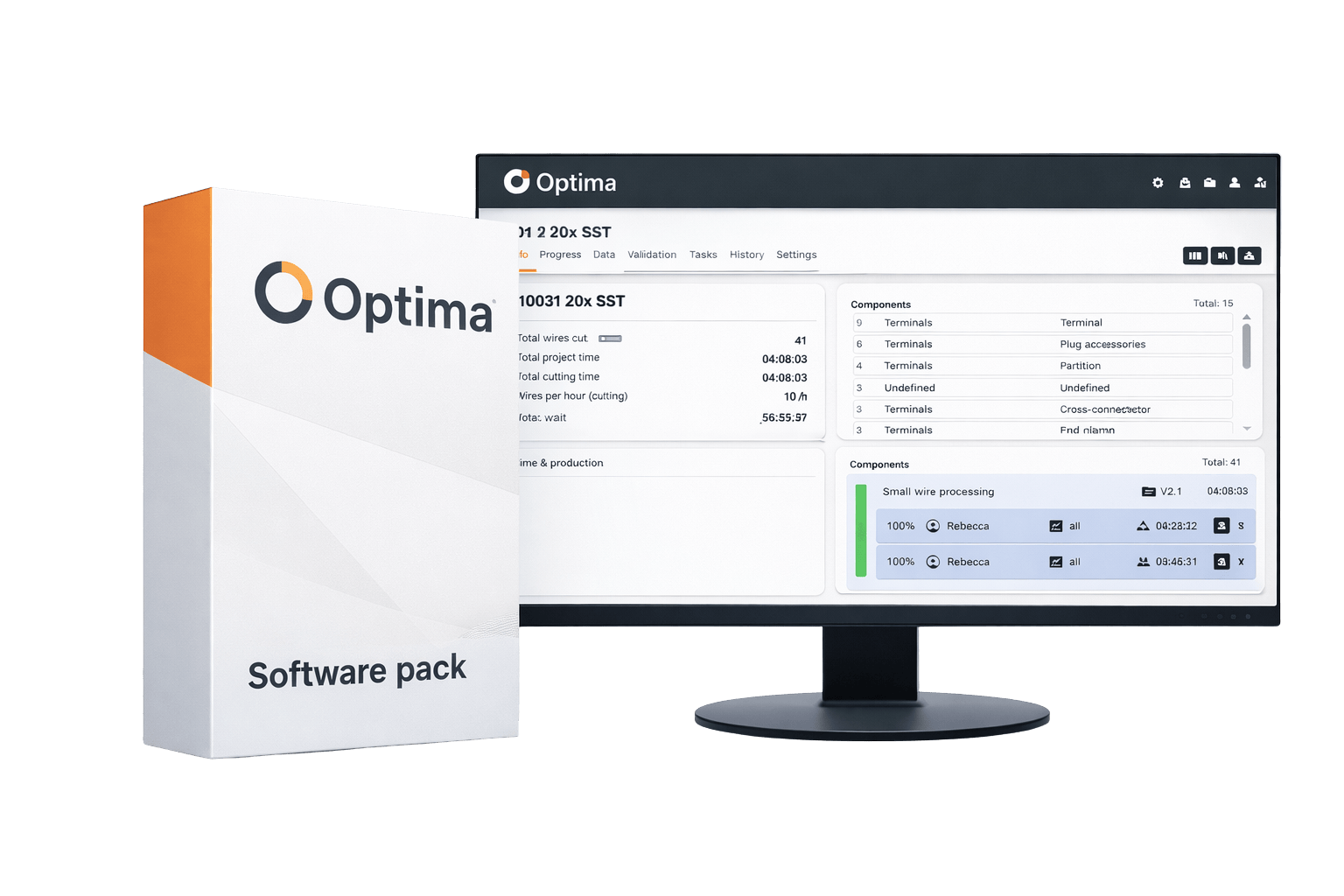

How Optimation helps with this

Optimation guides companies in the transition to data driven panel building.

With the Optima platform, engineering data, work preparation and production become one seamless process.

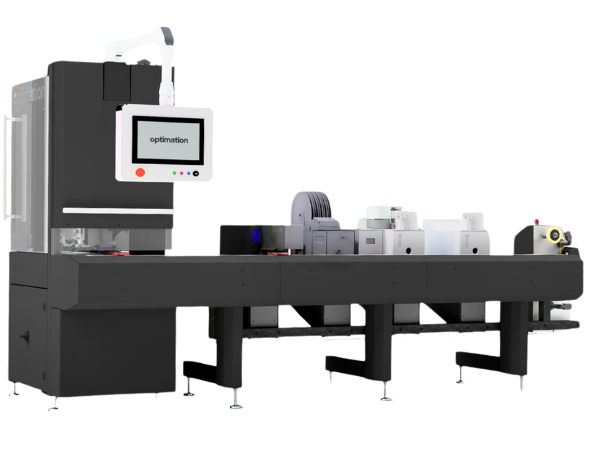

The Testudo and Castellum systems then turn that data into automated wire production.

But it always starts with the same step: improving schematics and getting engineering data in order.

That’s where we actively help.

Conclusion

Companies that invest in data driven production now gain in speed, quality, cost efficiency and scalability.

Digitalisation is not a luxury, but the foundation for modern panel building.