With smart software and advanced machines, we turn engineering data into error free wiring and efficient production.

With the Optima platform, Optimation brings software and practice together. The platform consists of several modules that are specifically developed for the digitization of panel building. Through smart integrations and an intuitive workflow, the entire process from engineering to production becomes transparent, controllable and scalable.

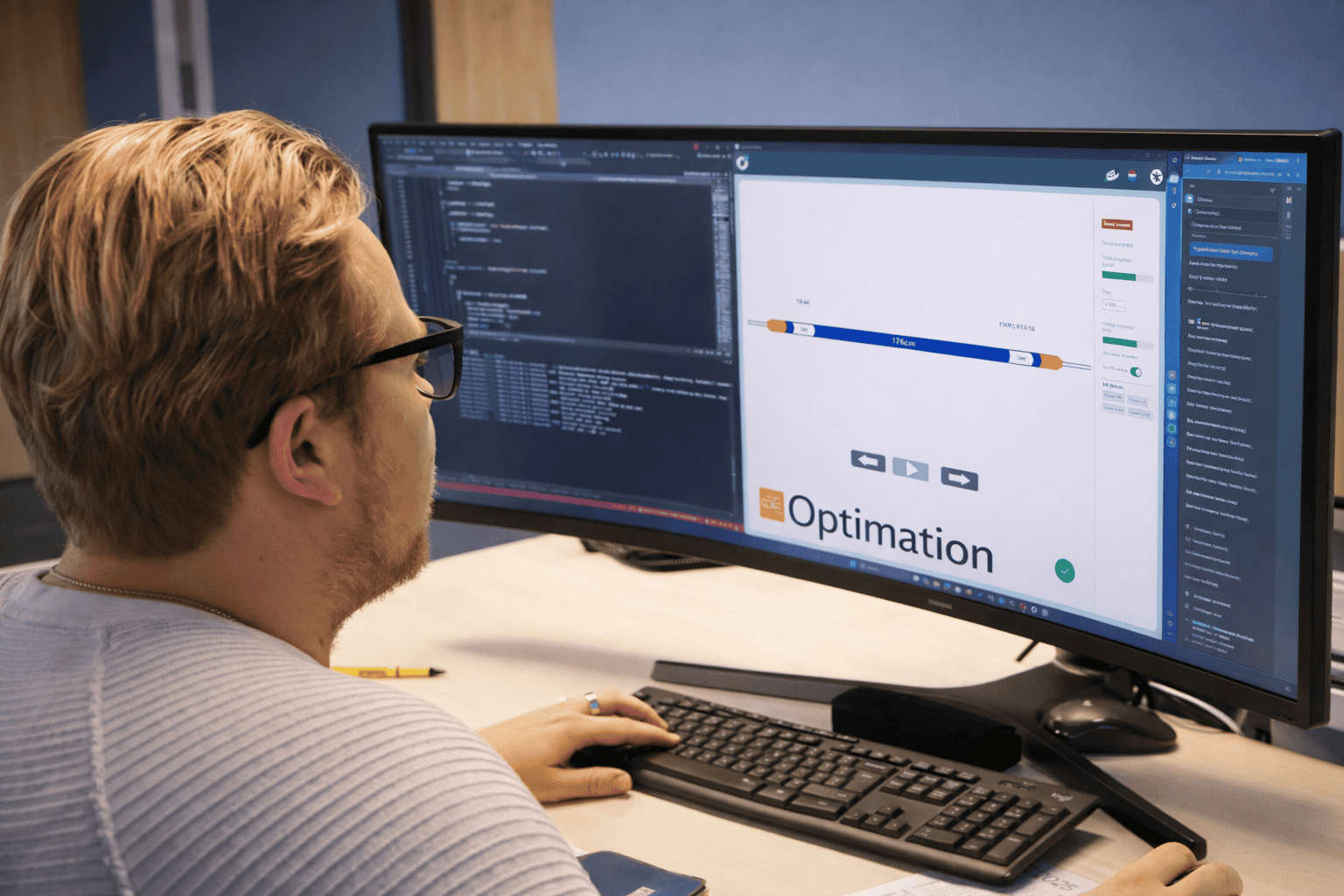

The Optima platform is the connecting factor between engineering, work preparation and production in panel building. The system retrieves data directly from your engineering software (such as EPLAN), checks it for completeness and structure, and then converts the information into concrete production control. Employees on the shop floor work with clear instructions, gain real time insight into their tasks, and deliver higher quality panels, faster and with fewer errors.

Whether you work manually, semi automatically with the Testudo or fully automated with the Castellum, Optima makes it possible.

With the Optima platform, Optimation brings software and practice together. The platform consists of several modules that are specifically developed for the digitization of panel building. Through smart integrations and an intuitive workflow, the entire process, from engineering to production, becomes transparent, controllable and scalable.

Through the connection with EPLAN and the automatic validation of data against company and project specifications, Optima helps you convert engineering data into reliable production information. This shortens your lead time, reduces the risk of errors and creates a foundation for scalable panel building.

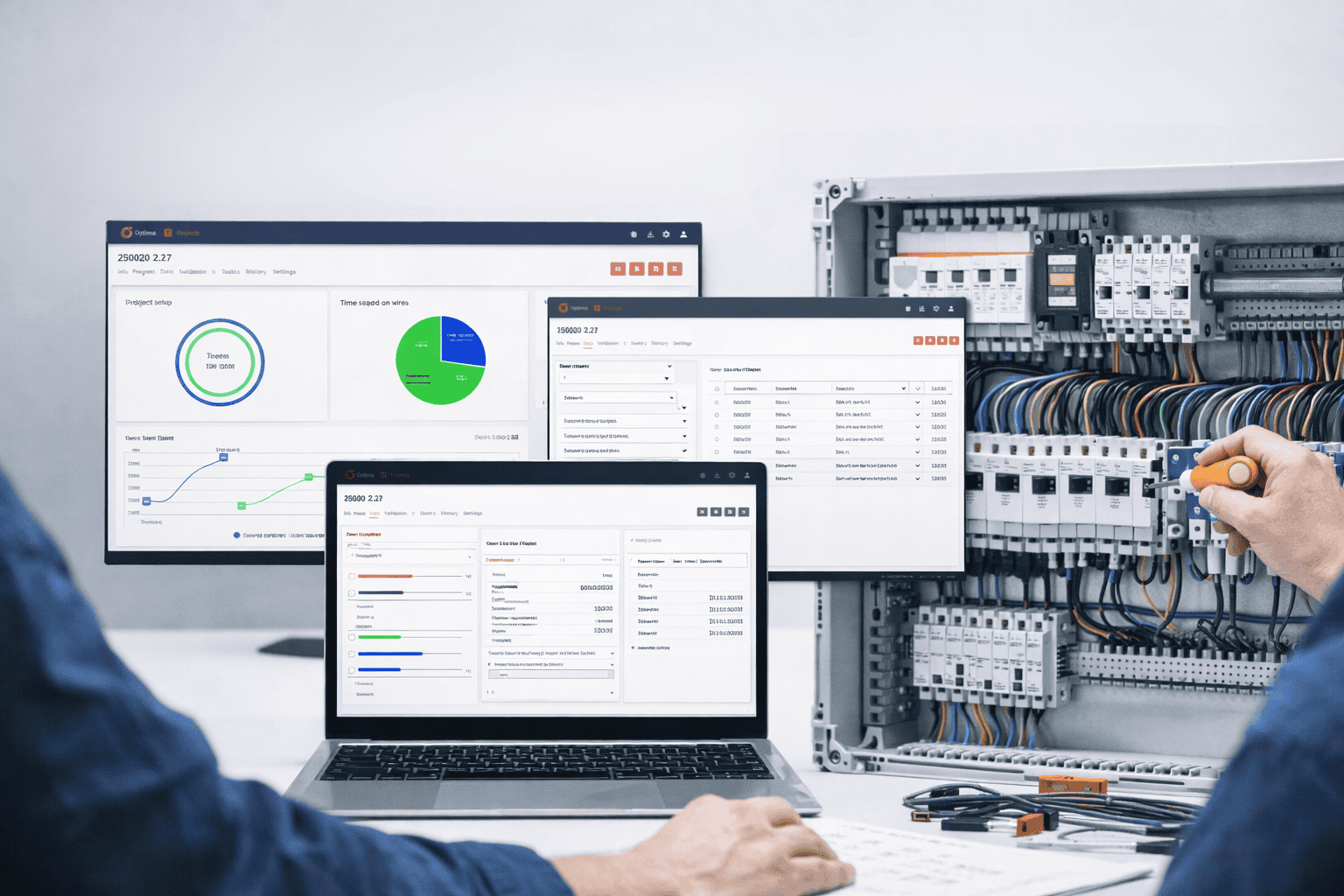

With Optima, your work preparer gains maximum control over the production process. Tasks can be planned efficiently, assigned to employees or machines, and tracked during execution. This allows you to use your capacity optimally, even when technical staff is scarce.

Thanks to real time monitoring, you can see exactly how each project and each employee is progressing in terms of timeline, time spent and performance. This gives you the insights needed to deliver projects on time and within budget, and to continuously improve.

In this recording you can see how the Optima platform controls the entire panel building process. It starts with the engineer who makes data from EPLAN available in Optima. The work preparer schedules and distributes tasks such as wire confection or wiring among employees or machines. On the shop floor, technicians and machines work in real time with this data. Everything runs according to the predefined build method. No paper, no miscommunication, but maximum control.

Do you still have questions about how Optima works in your organization? View the answers to the most frequently asked questions from our customers.

For panel builders, machine builders and OEMs that want to digitalise and make their production process scalable and future proof.

Digitalisation can be phased. You can start with Optima and add machines later. This spreads the investment while already giving you benefits from day one.

No. We align with your existing processes. Small steps ensure your team sees results quickly and the transition feels natural.

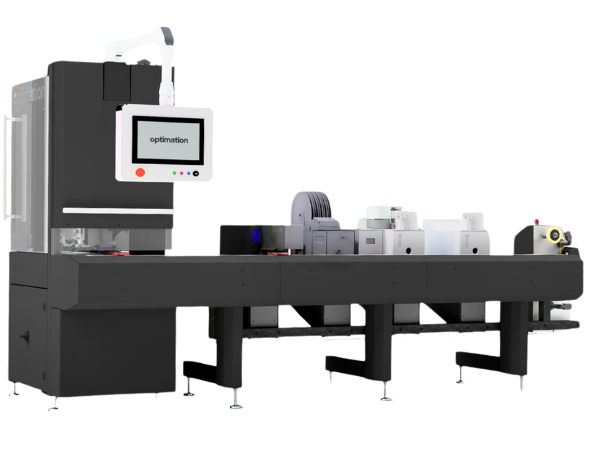

Testudo is a semi automatic machine for cutting and finishing wires.

Castellum goes a step further with fully automatic wire assembly including cutting, marking and finishing.

Yes. With the clear instructions in the Workfloor app, even non specialists can wire panels without errors.

We would be happy to show you how the Optima platform can digitize and accelerate your panel building process. Schedule a demo or contact us directly.