With smart software and advanced machines, we turn engineering data into error free wiring and efficient production.

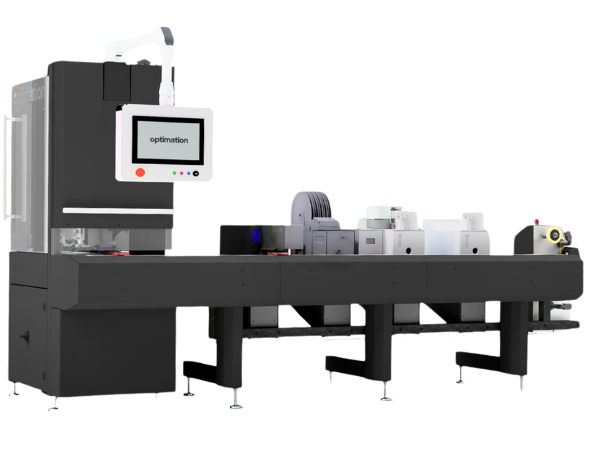

The panel building industry is changing faster than ever. Where wiring used to be done fully conventionally, we show that this process can be much smarter and more efficient. With the Optima platform you lay the digital foundation, but with Testudo and Castellum you take the real step toward automated wire confection.

These systems translate your existing EPLAN data directly into panel building and always produce wires in the correct length, order and quality. This way, you shift from traditional panel building to a data driven, automated approach, with more speed, fewer errors and complete control over your production.

The transition to digital panel building does not have to be a leap into the unknown. With Optimation, you choose a phased, feasible and proven approach. Our Optima platform forms the heart of a smart shop floor, where engineering data is directly translated into clear production instructions.

The Testudo (semi-automatic) and Castellum (fully automatic) systems connect seamlessly to this and automate the wire process step by step. This way you reduce your dependence on scarce technical staff, shorten lead times and increase both the quality and predictability of your production.

Here you will find answers to the most common questions about the Optima platform and the Testudo and Castellum systems. Is your question not listed? Feel free to contact us.

We start with an analysis of your current engineering approach, set up the data structure together and connect it to Optima. After that we train your team and, if desired, install the Testudo or Castellum.

That depends on your current data structure. Our consultants guide you step by step, from setting up EPLAN to implementing Optima and the machines.

Discover what the Optima platform, the Testudo and the Castellum can mean for your panel building.

We are happy to think along with you.